When choosing gloves for food handling, there are really three main things to consider material quality, meeting regulations, and whether they actually work for the job at hand. Regular gloves just won't cut it in food service environments because they need to stand up against tearing, getting pierced, and keeping chemicals from seeping into what we eat. Recent research published in the Journal of Food Protection back in 2024 found something alarming about 23 percent of gloves that claimed to be compliant still failed when tested for microbes. This shows why restaurants and food processors should take extra care when selecting suppliers and maybe even get third party testing done on their gloves before relying on them for safety.

Global standards establish the foundation for food-grade glove requirements:

| Standard | Key Focus | Jurisdiction |

|---|---|---|

| FDA 21 CFR 177 | Polymer safety & leaching | United States |

| EN 1186 | Chemical transfer limits | European Union |

| CFIA 2023-12 | Allergen cross-contact | Canada |

These frameworks require annual material testing, and regulatory data shows that 89% of food recalls since 2022 involved glove compliance failures, underscoring the critical role of adherence.

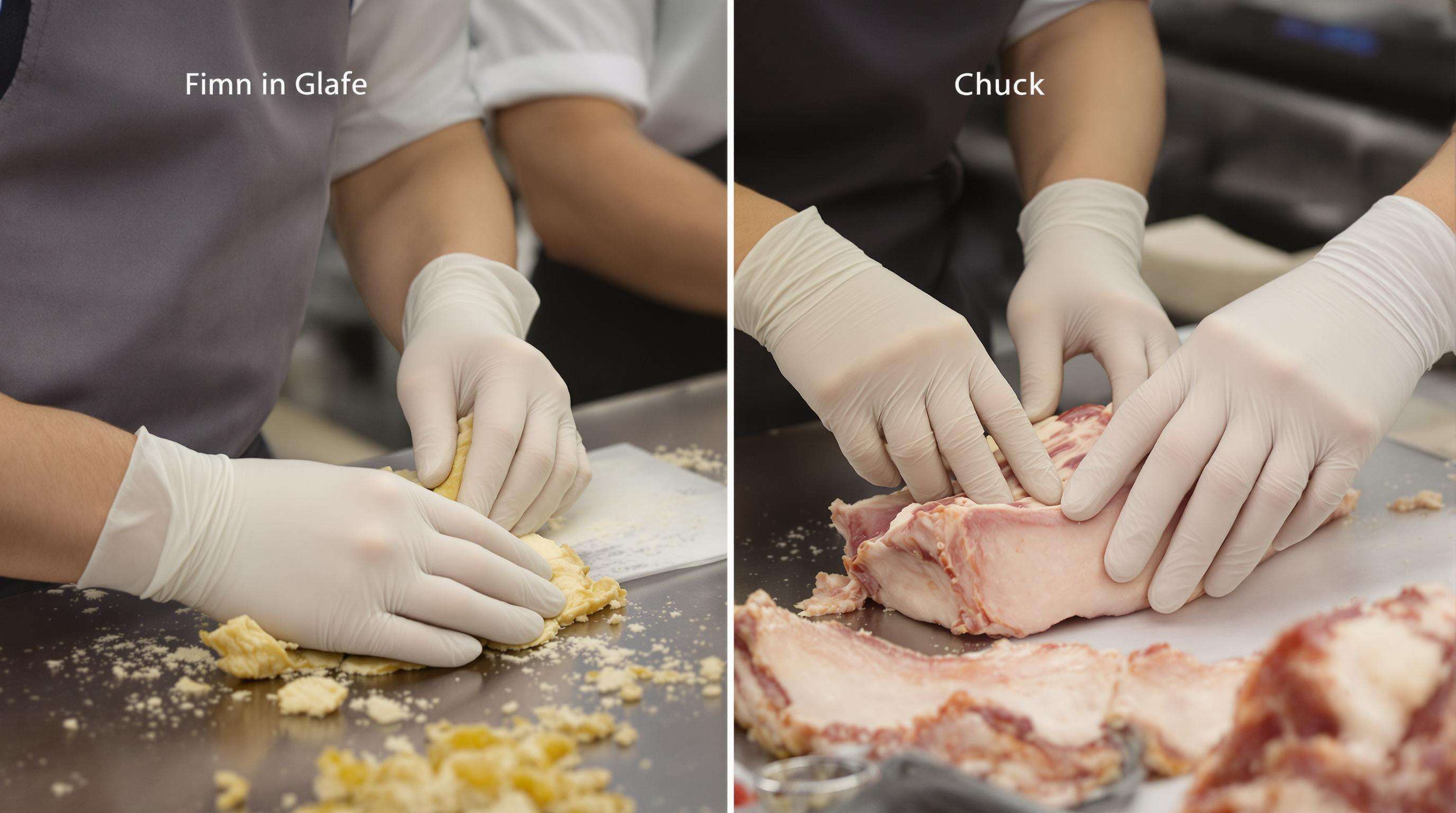

What kind of work someone does really determines what gloves they need on their hands. When dealing with bone saws during butchery tasks, workers should go for those ANSI A5 rated nitrile gloves that are at least 8 mil thick for proper protection against cuts. For making pastries where finger sensitivity matters a lot, thinner options around 3 to 4 mils with some texture work better. Kitchen staff working in greasy areas such as fry stations benefit from chlorinated nitrile gloves featuring those tiny surface textures. These special gloves can cut down on slips by roughly 40 percent based on tests run in actual commercial kitchens across the country.

Modern glove designs now feature XSâXXL sizing and color-coded thickness indicators, reducing improper use by 67% in USDA audits. Yet, 58% of food facilities unnecessarily use 6+ mil gloves for light prep tasks, inflating costs without safety gainsâdemonstrating how informed selection improves both compliance and efficiency.

Nitrile gloves are the preferred choice in food safety due to their resistance to biological, chemical, and physical hazards. Their synthetic polymer structure withstands oils and fatty foods while preserving tactile sensitivityâessential for handling delicate produce or precision tasks like sushi preparation.

| Property | Nitrile | Latex | Vinyl |

|---|---|---|---|

| Average tear resistance | 18â22 N force¹ | 15â18 N force¹ | 6â9 N force¹ |

| Chemical resistance | Acids, alkalis | Limited solvents | No oil resistance |

| Allergy risk | None | High (1â6% workforce²) | None |

This performance profile explains why 78% of commercial kitchens standardize on nitrile for high-risk tasks such as raw meat processing.

Latex gloves might be cheap for basic jobs but they come with real issues when it comes to allergies. Around 1 to 6 percent of folks working in food service end up with skin problems or breathing difficulties after being around latex for too long. Then there's vinyl which just doesn't hold up well when things get rough. These gloves tend to rip easily, about three times less resistant than nitrile when someone is cutting stuff all day. What about those hybrid options made from polyethylene? They don't really solve anything either. Workers still struggle with durability and heat resistance, especially in hot spots like bakeries where temperatures can be brutal.

The industryâs shift toward nitrile and advanced vinyl formulations addresses growing occupational health concerns. Latex-free gloves eliminate protein antigen exposure and align with OSHA disability accommodation guidelines. This transition has contributed to a 34% reduction in allergy-related worker compensation claims in food processing plants since 2022.

Nitrile gloves in the 3â5 mil range offer balanced protection across kitchen workflows:

Field tests show nitrile retains 94% structural integrity after 45 minutes of fish deboning, compared to 62% for latex.

Compliance starts with FDA 21 CFR 177, which prohibits materials from transferring harmful substances to food under normal use. NSF Internationalâs P155 certification enhances assurance by testing for chemical residues, puncture resistance, and durability. Together, these standards ensure safety across commercial kitchens and food packaging operations.

In Europe, Regulation (EC) No 1935/2004 mandates that food-contact materials must not compromise food safety and must display the âglass-and-forkâ symbol. EN 1186 complements this by simulating glove interaction with fatty, acidic, and aqueous foods, limiting chemical migration to 10 mg/dm² (EU Food Safety Authority, 2022).

The Canadian Food Inspection Agency (CFIA) enforces compliance under the Safe Food for Canadians Regulations. Gloves must pass migration tests for heavy metals and plasticizers, with penalties for repeat violations reaching $500,000 (CFIA Guidance Doc-24, 2023).

Third-party certifications validate safety through accelerated aging and food-simulant testing:

| Test Parameter | Threshold | Method |

|---|---|---|

| Phthalate Migration | â 0.1% by weight | EN 14372:2004 |

| Heavy Metals (Pb, Cd, Hg) | â 1 ppm | ISO 17294-2:2016 |

| Overall Migration Limit | â 10 mg/dm² | EN 1186 Series |

Certified gloves reduce contamination risks by 89% compared to non-certified alternatives (Global Food Safety Monitor, 2023).

When workers wear gloves that fit right, they experience about 27% less hand fatigue over an 8 hour shift according to research published in the Journal of Food Protection back in 2022. On the flip side, gloves that don't fit well tend to bunch up around the wrist or just feel tight everywhere, which actually makes simple kitchen tasks like chopping veggies take longer. We're talking roughly 15 extra seconds wasted every single minute spent cutting. For jobs requiring fine motor skills, glove design matters even more. Bakers working with pastries need those tapered finger shapes for better control. A recent look at 12 different commercial bakeries in 2023 confirmed this observation, showing how proper fit really does make a difference when creating intricate desserts.

Thickness must align with task demands:

| Task Type | Recommended Thickness | Key Benefit |

|---|---|---|

| Precision Baking | 4â6 mil | Maintains tactile sensitivity |

| Meat Processing | 8â10 mil | Resists punctures from bones |

A 2022 analysis of poultry plants found that 8-mil nitrile gloves reduced accidental lacerations by 63% compared to 5-mil versions, while still allowing sufficient dexterity for deboning.

Micro-textured palm patterns increase grip force by 40% when handling greasy tools or wet seafood (University of Guelph, 2023). In test kitchens, these gloves prevented 92% of avocado-slicing injuries compared to smooth-surfaced alternatives. For oily environments like fry stations, ensure textured surfaces are certified to resist food particle entrapment.

Gloves should be changed every 60â90 minutes during continuous use or immediately after switching tasksâsuch as moving from raw meat to ready-to-eat food preparation. Kitchens that implement hourly changes report 74% fewer cross-contamination incidents than those using ad-hoc practices. Key steps include:

Color-coded glove systems are now used by 57% of foodservice operators to prevent allergen cross-contact:

This visual system reduces protocol violations by 63% in fast-paced kitchens, according to NSF Internationalâs 2024 Kitchen Safety Report.

Effective training combines quarterly workshops with real-time reinforcement:

Operations using layered training achieve 89% sustained adherence, far exceeding the 52% seen with one-time orientations.

Copyright © 2024 Sichuan Samson Technology Co., Ltd - Privacy policy